Processes, Techniques, and Best Practices

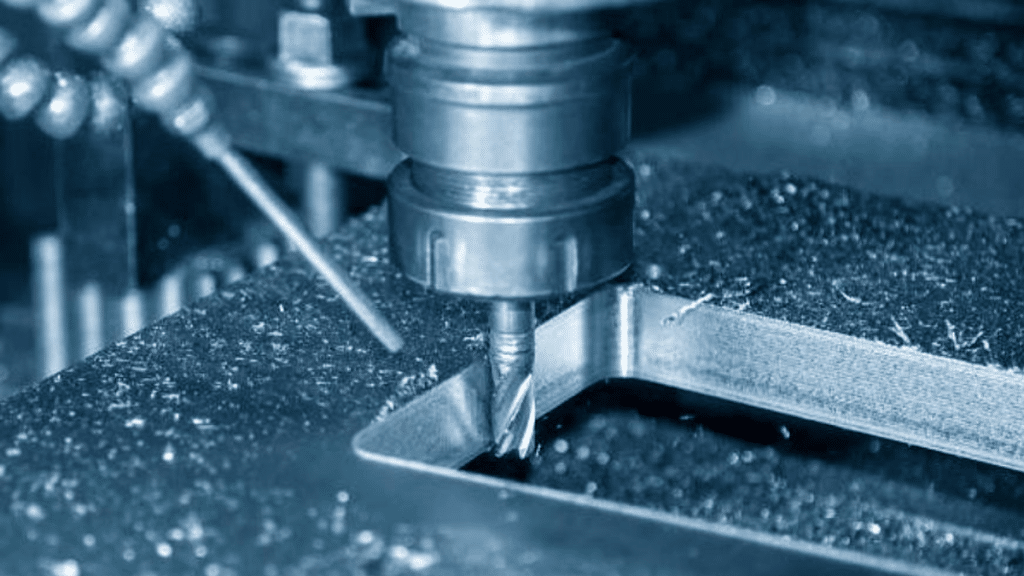

Milling is among one of the absolute most flexible as well as commonly utilized subtractive production procedures in contemporary market. Coming from model stores towards aerospace manufacturing facilities, milling devices form products along with accuracy as well as rate. Whether you are brand-brand new towards machining or even a skilled CNC driver, comprehending milling basics, process, as well as finest methods will help you enhance high top premium, decrease sets you back, as well as deal with complicated geometries.

Milling is among one of the absolute most flexible as well as commonly utilized subtractive production procedures in contemporary market. Coming from model stores towards aerospace manufacturing facilities, milling devices form products along with accuracy as well as rate. Whether you are brand-brand new towards machining or even a skilled CNC driver, comprehending milling basics, process, as well as finest methods will help you enhance high top premium, decrease sets you back, as well as deal with complicated geometries.

Exactly just what Is actually Milling?

Processes, Techniques, and Best Practices

Milling is actually a type of machining where a multi-point reducing device rotates at broadband as well as traverses about a fixed workpiece towards eliminate product. Instead of single-point switching on a lathe, milling cutters can easily reduce in axial as well as radial instructions, allowing the development of:

Level surface areas

Ports as well as pockets

Complicated 3D shapes (e.g., mold and mildews as well as dies)

Helical as well as threaded functions

Woman who tricked her way into men-only Magic Circle finally allow

Subtractive Production

Unlike additive procedures (3D printing), milling subtracts product in managed passes up till the component suits the CAD design. Essential benefits consist of:

Limited tolerances (±0.005″ or even better)

Wide product compatibility (steels, plastics, compounds, wood)

Soft surface area surfaces along with very little subsequent completing

The innovation of the very initial milling device through Eli Whitney in 1818 indicated a transforming factor, changing handbook declaring along with mechanized reducing as well as allowing compatible components in production

Exactly just how Milling Jobs: The Center Procedure

Style & CAM Programs: CAD design → CAM software application produces G‑code device courses.

Configuration & Fixturing: Protect workpiece along with vises, secures, or even customized components towards prevent resonance.

Device Choice & Launching: Suit device product (carbide, HSS), geometry (covering, flute count), as well as dimension towards the task.

Specification Setup: Input pin rate (RPM), feed price (IPM or even mm/min), deepness & size of reduce.

Completely dry out Operate: Mimic device course along with pin off towards verify no accidents.

Komentar

Posting Komentar